Treudd is a stool made from three identical plywood parts, innovatively produced to ensure both functionality and sustainability.

TREUDD

Treudd is a stool that consists of three corners. As a stool, it is well suited for mobile spaces, but it also serves its purpose at home as a seat or side table. The aim of the project was to find a solution to produce a closed, threedimensional plywood part.

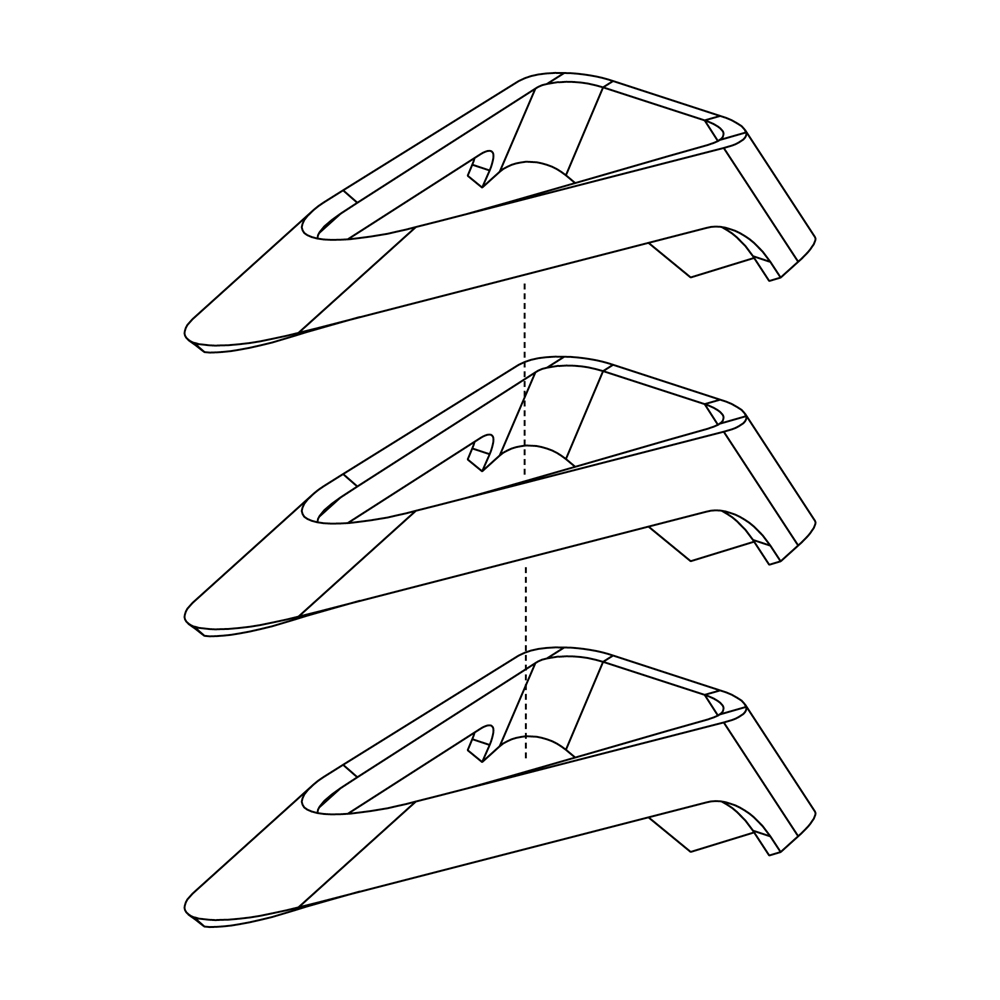

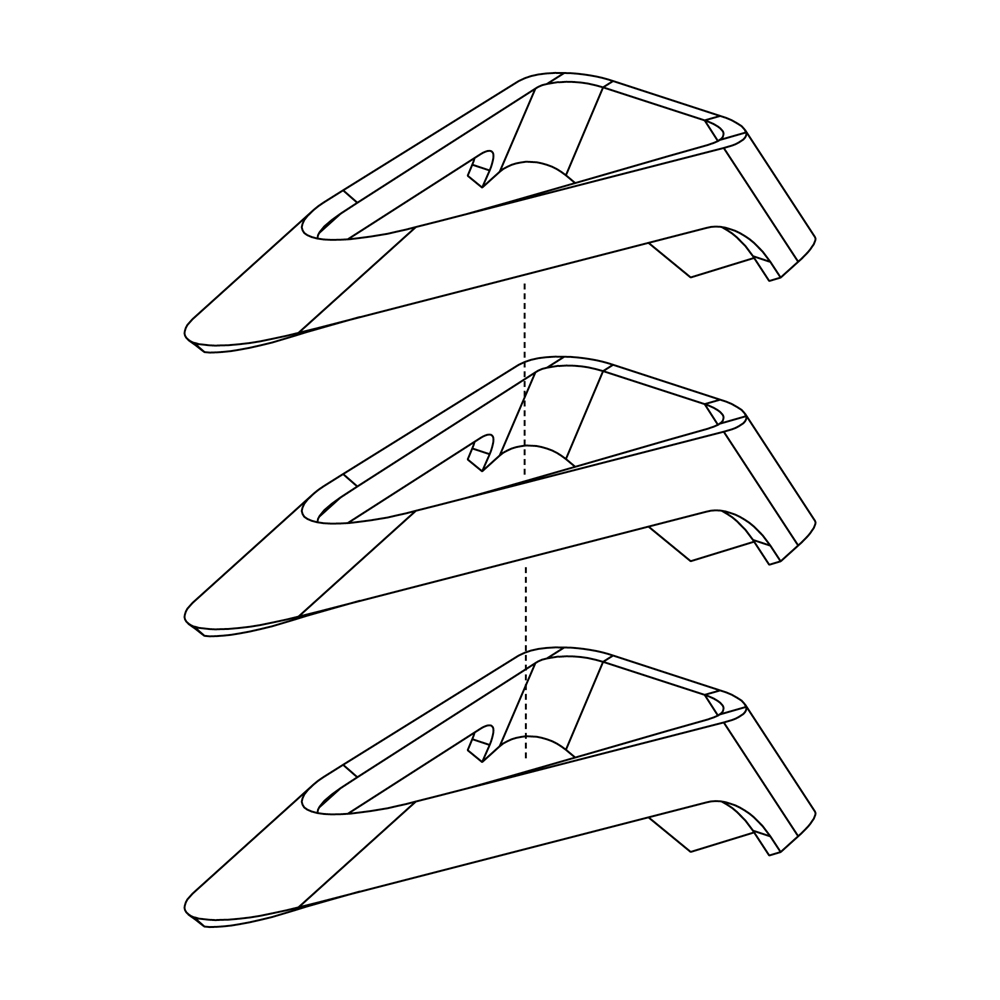

The three corners that make up the stool reflect the process in which it was possible to produce just such a shape from plywood.

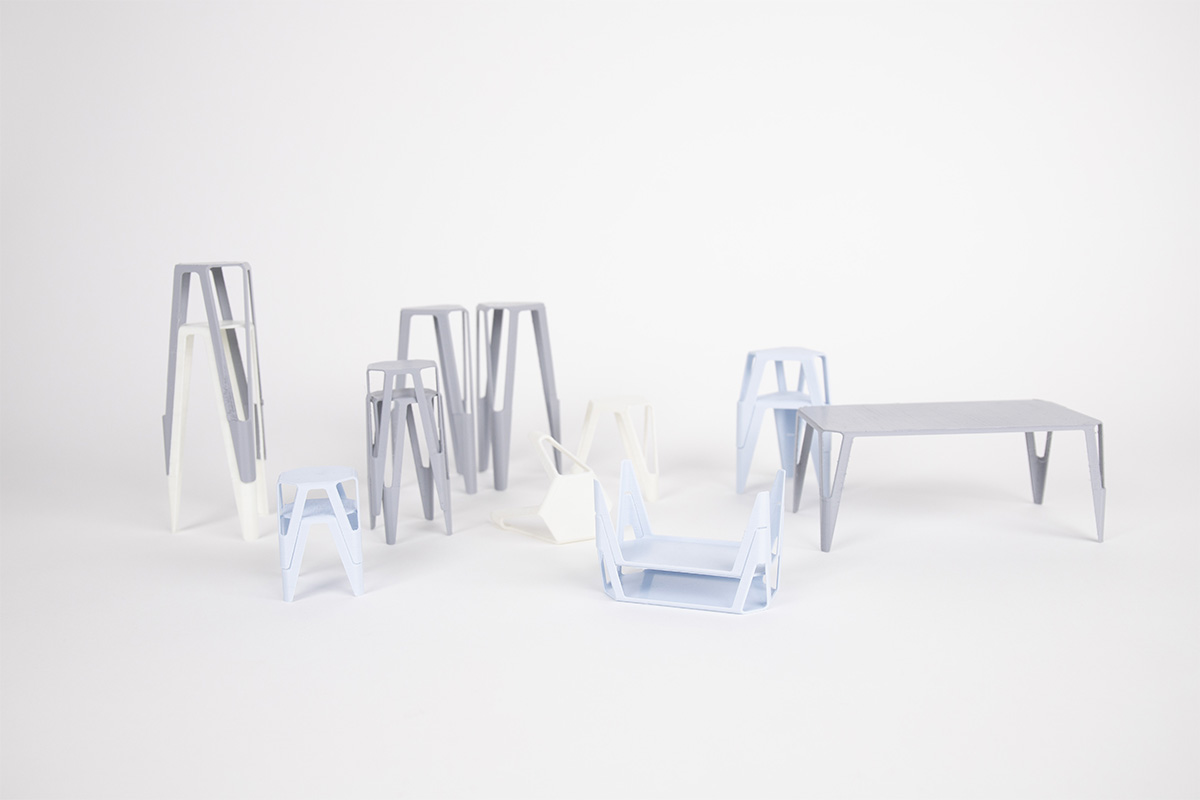

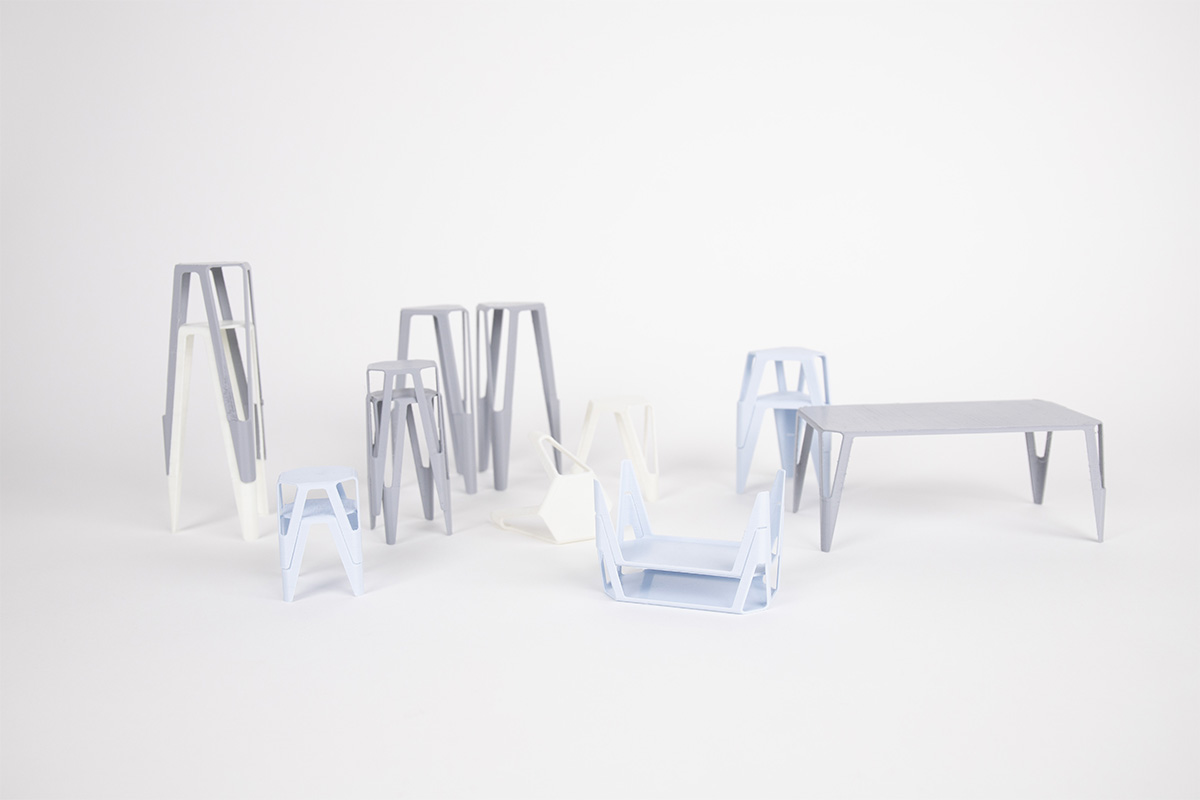

The shape of the plywood parts allows Treudd to be stacked as high as desired. As the stools are stacked, they create a visually united image. Due to its three-dimensional shape, the stool remains remarkably lightweight, with only 1.5 kg!

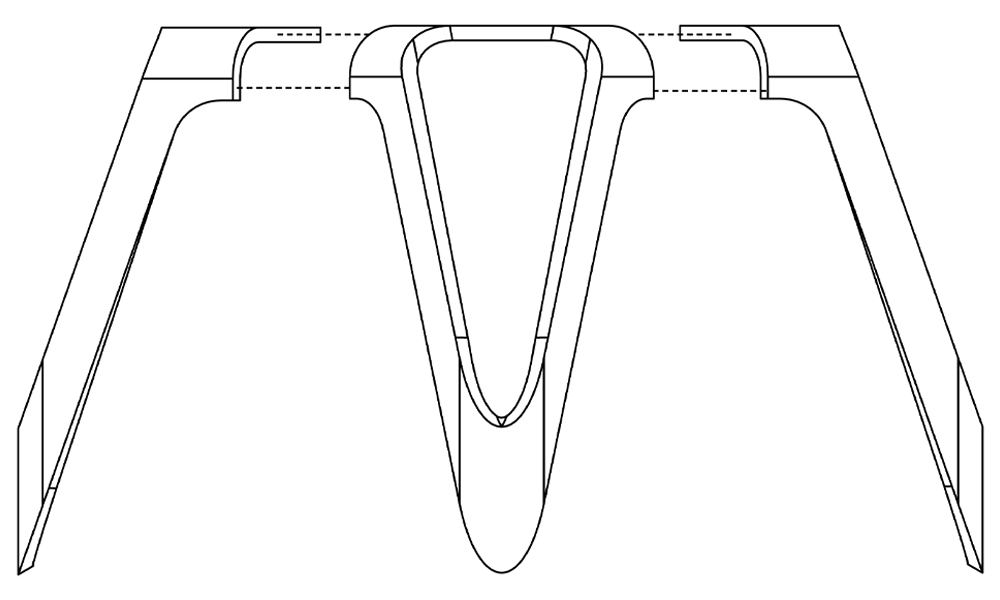

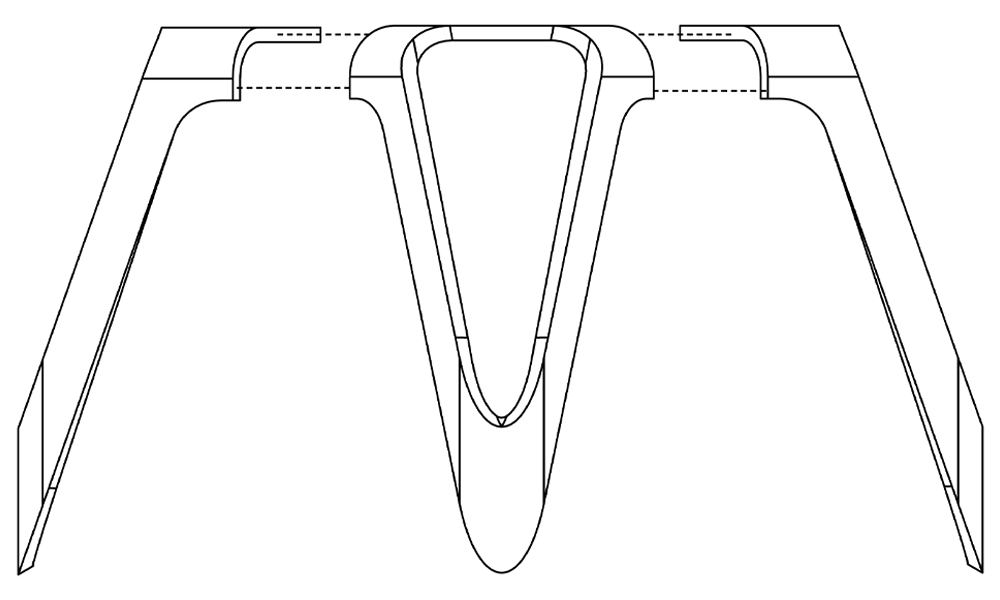

If three surfaces meet, a corner is always created. Strictly speaking, the corners that make up Treudd are not real corners, they only have a point where two surfaces meet. The idea was to reduce a corner in such a way that it does not lack stability and can still be converted into plywood. A corner that is two-dimensional at the points where the surfaces meet, but nevertheless connects three flat surfaces and therefore remains so stable.

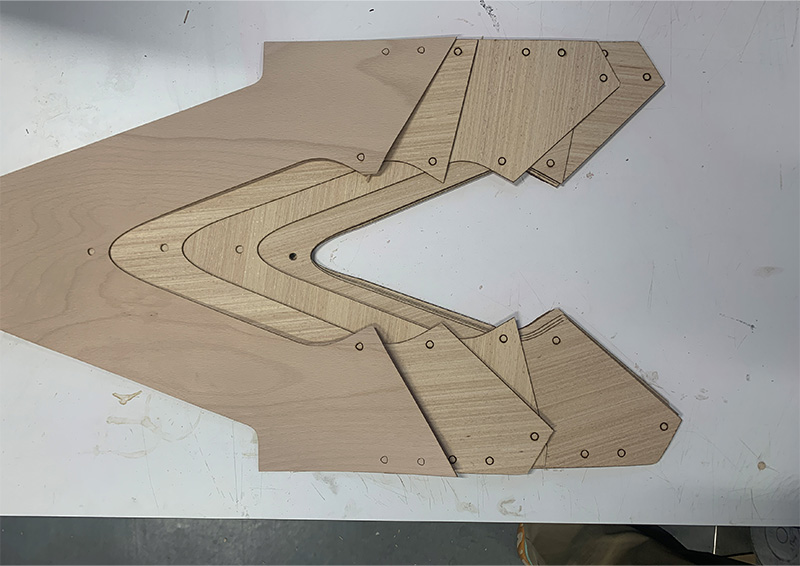

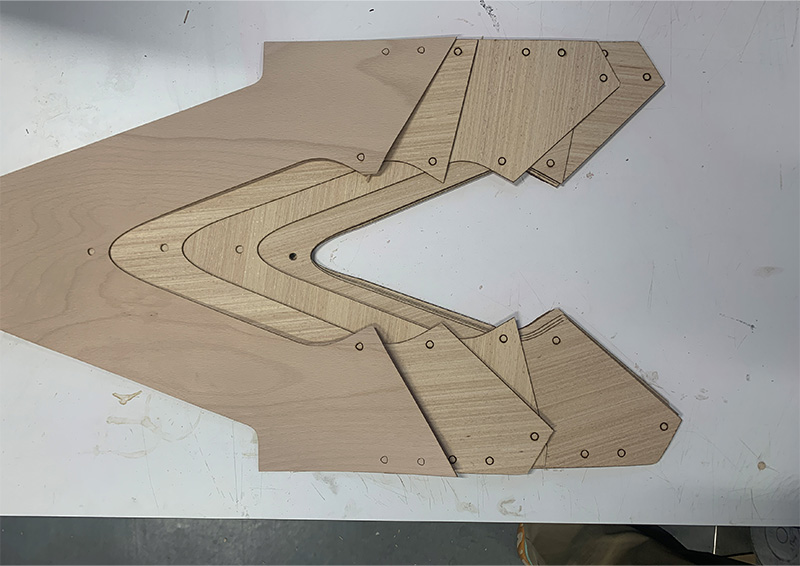

To produce the corners from plywood, the surfaces of previously built CAD models were unwound and enlarged. These unwindings are separated at one point, yet to ensure structural integrity, two different cutting patterns were designed. These patterns are always laid on top of each other in alternation. Subsequently, the veneer patterns are laser-cut and then pressed into shape. Later, the plywood parts are cut using a 5-axis CNC mill.

The three wooden corners are glued together using wooden dowels. It would also be possible to work with reclosable connectors so that the stool can be assembled and disassembled at any time.

The disassembled stool can be flat-packed, as the parts nest neatly onto each other.

TREUDD

Treudd is a stool made from three identical plywood parts, innovatively produced to ensure both functionality and sustainability.

Treudd is a stool that consists of three corners. As a stool, it is well suited for mobile spaces, but it also serves its purpose at home as a seat or side table. The aim of the project was to find a solution to produce a closed, threedimensional plywood part.

The three corners that make up the stool reflect the process in which it was possible to produce just such a shape from plywood.

The shape of the plywood parts allows Treudd to be stacked as high as desired. As the stools are stacked, they create a visually united image. Due to its three-dimensional shape, the stool remains remarkably lightweight, with only 1.5 kg!

If three surfaces meet, a corner is always created. Strictly speaking, the corners that make up Treudd are not real corners, they only have a point where two surfaces meet. The idea was to reduce a corner in such a way that it does not lack stability and can still be converted into plywood. A corner that is two-dimensional at the points where the surfaces meet, but nevertheless connects three flat surfaces and therefore remains so stable.

To produce the corners from plywood, the surfaces of previously built CAD models were unwound and enlarged. These unwindings are separated at one point, yet to ensure structural integrity, two different cutting patterns were designed. These patterns are always laid on top of each other in alternation. Subsequently, the veneer patterns are laser-cut and then pressed into shape. Later, the plywood parts are cut using a 5-axis CNC mill.

The three wooden corners are glued together using wooden dowels. It would also be possible to work with reclosable connectors so that the stool can be assembled and disassembled at any time.

The disassembled stool can be flat-packed, as the parts nest neatly onto each other.